Robot Mobility: Designing the drive system/

The three most popular types of locomotion for a robot are:

Wheels:

Wheels are usually the simplest and most versatile choice for robot mobility. Wheel size will depend on the size of your robot and the type of terrain it will travel over. Small wheels will have difficulty driving over items such as carpet, uneven flooring, thresholds that separate one room from another, small pebbles and rocks, etc. The larger the robot the larger the wheels;) Two other factors to consider are the weight of your robot and the type of material that the wheels are made of. If your robot will be considerably heavy, say over 100 lbs.; you should choose wheels that are made of a fairly dense rubber or plastic. Will they leave marks on floors like hardwood, tile or linoleum? Better be sure. You don’t want your robot to be an unwelcome guest. Surplus wheelchairs tend to be a good choice as they are engineered to carry a good amount of weight, the gearing and variable speed drive system is built in and you can hack the controls to suit your needs.

Legs:

Very few people who attempt to build a large heavy robot take on the challenge of using legs for locomotion. Many questions come up such as:

- How many legs will there need to be for good stability?

- How do the legs need to move in order to propel the robot forward, backward or turn?

- How many joints will the legs need to work smoothly?

- How big do the legs need to be to support the robot?

The mechanical design and programming can be very tricky and complex. Four legged robots tend to be easier to balance but, steering and locomotion are harder to achieve. Hexapod robots are better equipped to walk at faster speeds without falling over and are better at making turns.

Tracks:

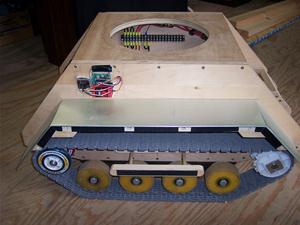

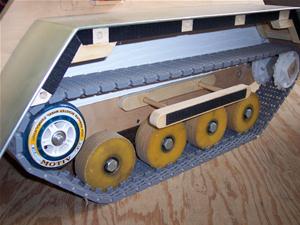

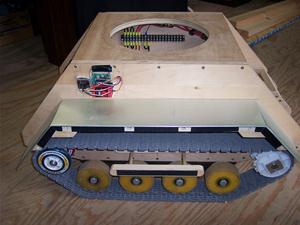

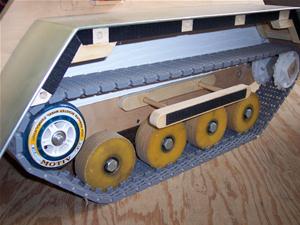

Tracks are my personal favorite mainly because they look so cool! They can be fairly hard to design and build but have some advantages over wheels or legs. Tracks act like giant wheels and provide terrific traction depending on what they are made of. Due to the way a track drive is constructed it can support quite a bit of weight and provide good stability (another reason I chose them). The length of each track is usually as long as the robots base. Their width will depend on the size and weight of your robot and will usually be 2 to 4 inches wide.

The length of the robot base will determine how many idler wheels are needed. The idler wheels will generally travel in a channel that is formed into the tracks. Some tracks have one single fin-like protrusion in the center that requires the idler wheels to have a groove cut into them. Or the idler wheels can be doubled up with a small space between each set. Whether it is a channel or fin, either one helps keep the tracks from being thrown off as the robot moves or turns. Each track will also need a drive sprocket and some adjustable method to keep them at the correct tension. The Razor scooter wheels shown in the picture are mounted on an axle at the rear of the robot base. The axle can slide in a slot and is adjusted by a pair of bolts that push against it to tension the tracks. More details and pictures will be coming soon in future chapters. Tracked robots can travel over almost any type of surface. Even snow! However, the biggest drawback is the damage they can do to flooring and carpets especially when making turns. Tracked robots should usually be driven outside.

Tracks are my personal favorite mainly because they look so cool! They can be fairly hard to design and build but have some advantages over wheels or legs. Tracks act like giant wheels and provide terrific traction depending on what they are made of. Due to the way a track drive is constructed it can support quite a bit of weight and provide good stability (another reason I chose them). The length of each track is usually as long as the robots base. Their width will depend on the size and weight of your robot and will usually be 2 to 4 inches wide.

Tracks are my personal favorite mainly because they look so cool! They can be fairly hard to design and build but have some advantages over wheels or legs. Tracks act like giant wheels and provide terrific traction depending on what they are made of. Due to the way a track drive is constructed it can support quite a bit of weight and provide good stability (another reason I chose them). The length of each track is usually as long as the robots base. Their width will depend on the size and weight of your robot and will usually be 2 to 4 inches wide.  The length of the robot base will determine how many idler wheels are needed. The idler wheels will generally travel in a channel that is formed into the tracks. Some tracks have one single fin-like protrusion in the center that requires the idler wheels to have a groove cut into them. Or the idler wheels can be doubled up with a small space between each set. Whether it is a channel or fin, either one helps keep the tracks from being thrown off as the robot moves or turns. Each track will also need a drive sprocket and some adjustable method to keep them at the correct tension. The Razor scooter wheels shown in the picture are mounted on an axle at the rear of the robot base. The axle can slide in a slot and is adjusted by a pair of bolts that push against it to tension the tracks. More details and pictures will be coming soon in future chapters. Tracked robots can travel over almost any type of surface. Even snow! However, the biggest drawback is the damage they can do to flooring and carpets especially when making turns. Tracked robots should usually be driven outside.

The length of the robot base will determine how many idler wheels are needed. The idler wheels will generally travel in a channel that is formed into the tracks. Some tracks have one single fin-like protrusion in the center that requires the idler wheels to have a groove cut into them. Or the idler wheels can be doubled up with a small space between each set. Whether it is a channel or fin, either one helps keep the tracks from being thrown off as the robot moves or turns. Each track will also need a drive sprocket and some adjustable method to keep them at the correct tension. The Razor scooter wheels shown in the picture are mounted on an axle at the rear of the robot base. The axle can slide in a slot and is adjusted by a pair of bolts that push against it to tension the tracks. More details and pictures will be coming soon in future chapters. Tracked robots can travel over almost any type of surface. Even snow! However, the biggest drawback is the damage they can do to flooring and carpets especially when making turns. Tracked robots should usually be driven outside.

No comments:

Post a Comment