Power Requirements:

You must give careful thought to choosing the right batteries for your robot. The power supply system for the robot must be able to handle the voltage and current ratings of the motors, lighting system, sound system, and control circuitry.

You must give careful thought to choosing the right batteries for your robot. The power supply system for the robot must be able to handle the voltage and current ratings of the motors, lighting system, sound system, and control circuitry.It is a good idea to test each type of motor used on your robot to find out how much current is needed when they start up, when they are running under normal load conditions, and when they stall.

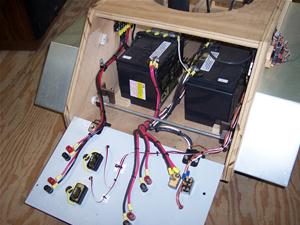

Most robot designs will require several different regulated voltage sources. The drive motors may require +12 or +24 volts at up to 30 amps. The electronic subsystems may require voltages such as +5, +6, +9, and +12 volts. Multiple voltages can be handled several different ways. The best method is to use separate battery supplies. One heavy-duty lead acid set of batteries to provide power for the drive motors and any other motors used on the robot such as: waist, neck, and arm motors. Another smaller set of gel-cell batteries should be used to power all the electronic subsystems.

The reasoning behind this is because motors generally distribute a lot of electrical noise throughout the power wires. Electronics can be extremely sensitive to electrical noise. Using two separate sets of batteries nearly eliminates these problems. However, other problems can occur due to the arcing of motor commutators, which can cause rf interference with remote control and wireless video/audio systems. Another reason is that in a one-battery system, the current surge that occurs when a motor is activated may zap all the juice from the electronics. This sudden dip in power might cause certain circuits to fail or become erratic causing the robot to lose control. Not good.

Be sure to place smaller capacitors such as 0.1uf across the power rails wherever power enters or exits each circuit board. These are used as “de-coupling” capacitors. Other “de-coupling” capacitors should be added as close as possible on the circuit boards across the power inputs for “clocked” logic IC’s, especially counters and flip-flops.

Warnings

- Batteries can deliver a large amount of current. If the leads of the battery accidentally touch each other or there is a short in the circuit somewhere, the wires may melt a start a fire! The smoke from such a fire is poisonous.

- Batteries can explode. When a battery is charging, it gives off hydrogen gas. Hydrogen is flammable and will explode if there is a spark or ignition source near the battery. Always provide good ventilation when the batteries are charging.

- ALWAYS wear safety chemical goggles and rubber gloves when handling or hooking up batteries. I even use a face shield. Lead-acid batteries contain sulfuric acid, which can burn you skin or eyes if any leaks out or is splashed in your face.

- Always check that you have hooked up the battery with the correct polarity. Hooking up a battery backwards can damage the battery, charging system, and electronics.

Voltage

Most rechargeable batteries are recharged about 20 percent higher than their specified rating. As an example, the 12-volt battery in your vehicle is charged to about 14 volts.Most batteries are considered dead when their power rating reaches 80 % of their rated voltage. When you are testing your robot’s electrical systems, keep a careful eye on the condition of the batteries with a hand-held voltmeter. Make these tests while the batteries are in use. Otherwise, the test results may be erroneous.

Amp-Hour Current

The amp-hour rating for a battery is the amount of power, in amps or milliamps, that the battery can deliver in a specified time period.Some people have been taught that amp-hour means that the battery will provide its rated current for 1 hour before going kaput. Some say if a battery is rated at 5 amp-hours, it can provide 5 amps continuously for 1 hour or 1 amp continuously for 5 hours. This is a misconception. The 5 Ah rating is actually taken at a 10 to 20 hour discharge interval. The battery is tested for 10 or 20 hours at a low or medium discharge rate. After the time period has finished, the battery is checked to see how much energy it has left. The rating of the battery is calculated by taking the difference between the discharge rate and the reserve power then multiplying it by the number of hours under test.

Tips

- You should always choose a battery that has an amp-hour rating 20 to 40 percent more than what you need to power your robot.

- Be sure to follow the manufacturer’s instructions for recharging your batteries.

- If you are not sure of the specific charge rate you should limit the recharging level to 1/10th the amp-hour rating of the battery.

Fuses

You must choose the correct type of fuse to protect you robot from major malfunctions. Fuses help to eliminate the problems caused by short circuits or power overloads. Remember how much blood, sweat and tears went into building all this. You don’t want it to go up in a puff of smoke.Warnings

- Installing a fuse that is rated too far above your current requirements may not blow when a malfunction occurs. This could result in a fire!

- Be extra careful when wiring you power supply system. Triple check your work. A mistake here will cost you dearly.

Recall that motors draw excessive current during start up so make sure your fuse is the slow-blow type. Unless you like changing the fuse each time the drive motors kick in.

You should also install a fuse for each of the separate regulated supplies required for your robot. Base the fuse size on the current needs of whatever subsystem they are supplying.

Note : I am not responsible for any harm you cause to yourself, others or any damage you cause while attempting to replicate what is discussed in these or future articles. Please use good judgment and the proper personal protective equipment to protect yourself. If you feel that something I have posted is wrong or needs correcting please feel free to bring it up.

No comments:

Post a Comment